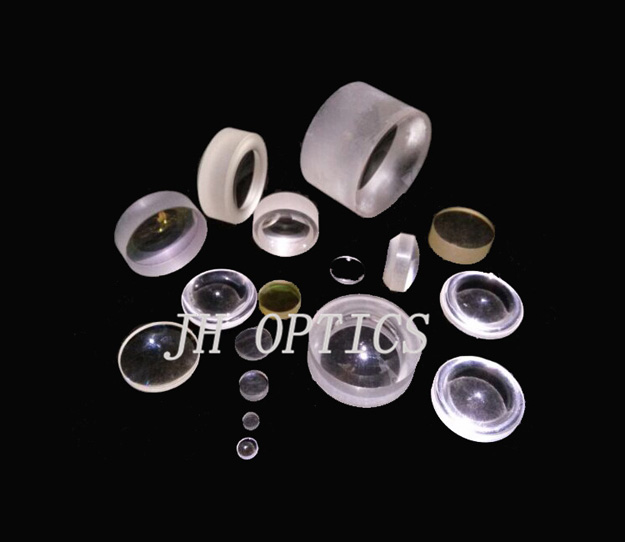

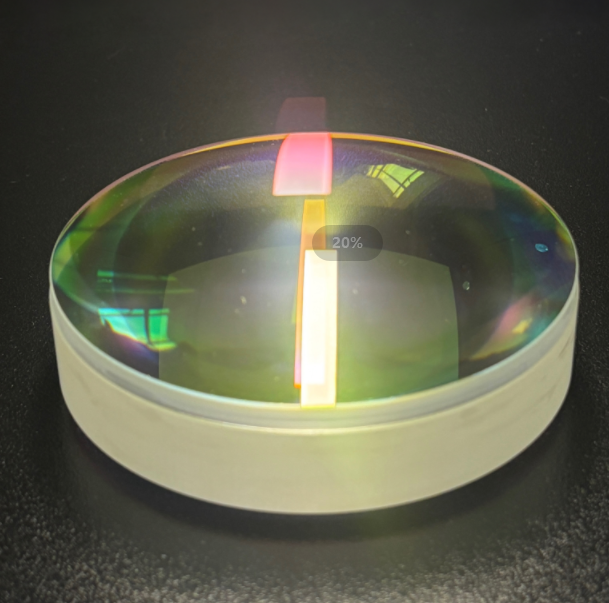

Spherical lenses are a crucial component in nearly all optical systems, accounting for more than 70% of our product offerings. We continuously research and explore more environmentally friendly, efficient production processes that align with our management system. We have established a system for correcting defective products, and all our efforts are aimed at enhancing the perfection of our products. Ultimately, this is to provide better products and services to our customers and partners.

Our extensive knowledge of spherical lens products stems from the accumulation of production and processing experience, as well as the cooperation with various customers during the grinding and adjustment processes. All our achievements are hard-earned and constitute a valuable asset.

The processing requirements for spherical lenses vary in different optical systems. For instance, in laser systems and high-power optical systems, the focus is on the surface roughness of the lenses. In contrast, visual imaging systems have stricter requirements in terms of surface shape, RMS, eccentricity, and other parameters. Our company boasts both a traditional polishing workshop and a digital polishing workshop, enabling us to meet the diverse precision requirements of our customers' purchasing plans.

Material Suppliers for Our Production Lenses:

Chengdu Guangming (CDGM), SCHOTT, OHARA, HOYA, Corning, and other material manufacturers with ROHS certification.

Lens Size Range Options:

Diameter (Dia): 0.5mm to 500mm

Radius: 0.5mm to ∞ (flat at infinity)

Eccentricity / Centration: Measurable up to 3 arc-seconds using our eccentricity meter.

Surface quality(S/D): We can provide the highest grade better than 10/5, or we can evaluate based on your actual application requirements.

Surface Flatness: We offer products with surface flatness better than λ/20. Our interferometer standard lens surface shape exceeds λ/20 specifications.

Transmitted Wavefront (RMS): We provide actual measurements for this parameter. The appropriate shape of the product ensures favorable processing performance. Evaluation of results will be based on the material and shape.

Other Dimensional Parameters: For side droop, concentricity, and other dimensional parameters, please contact us for an evaluation tailored to your specific product.

Note:

The technical parameters that can be processed need to be evaluated based on drawings or specific requirements. The achievable accuracy level in actual production is influenced by material properties, shape requirements, processing technology, equipment, technicians, and testing equipment. We understand the field of optical lens processing. If you have any questions, please contact us.

Plano-convex lens

This kind of lens is applied to gathered beam imaging and scatterign, detection, lasers and any other optical application.

Plano-concave lens

Plano-concave lenses have one flat and one concave surface.

Biconcave lens

Bi-concave spherical lenses have two concave surfaces.

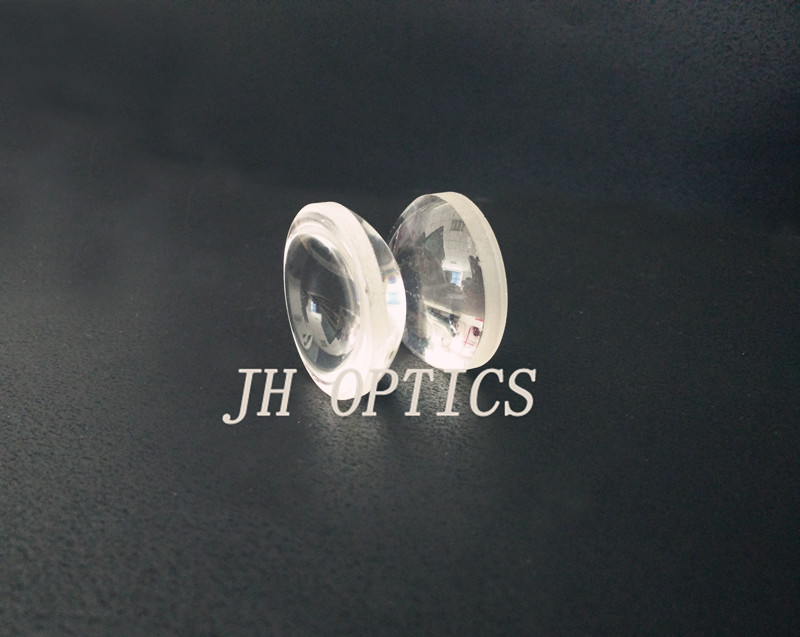

Biconvex lens

Bi-convex or symmetric-convex lenses have two convex surfaces, the surface can have the identical or different radii.

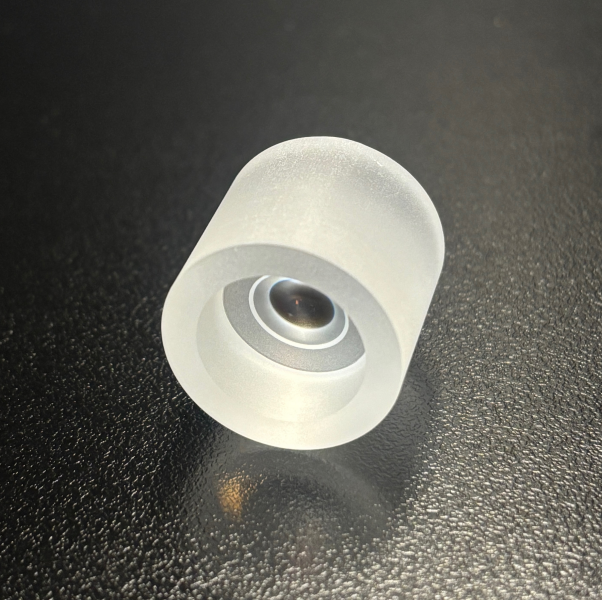

Meniscus lens

Meniscus lenses have a convex and a concave surface.

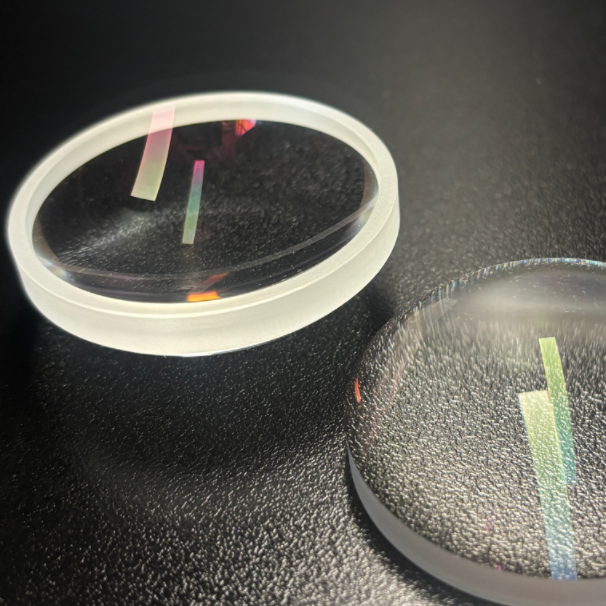

Achromatic lens

Achromatic lenses are computer optimized to correct for on-axis spherical and chromatic aberrations.