Jiheng Optics mainly focus on custom products and we use traditional polishing process. With the popularization of numerical control polishing system, low surface quality request products have already not been produced by us any longer. The main applications of our products is laser system, lab instrument, aviation optical nacelle, military night imaging system.

(Large Magnesium Fluoride(MgF2) windows polishing, only the material cost over US$25,000)

Jiheng Optics specializes in IR optical material polishing., such as Calcium Fluoride(CaF2), Magnesium Fluoride(MgF2), Germanium(Ge), Silicon(Si), Zinc Selenide(ZnSe). These five materials are often polished in our workshop, we can supply the products with the same quality level as some famous optical component companies located in US, UK. There are three principal factors to ensure the products quality, the first one is rich experience of our polishing engineer, the second one is precise control of polishing process, and the last one is correct choose of polishing powder (we import it from an US lab) . But some other kinds of IR material are not sure for Jiheng Optics, such as KBr,GaAs, BaF2.,etc

Usually some customers are in doubt with our pricing, thinking that the unit price change too much when the purchasing quality is different. The following example will show you the reason.

When polishing the parts, we need to fix them(not polished windows, lens) on a plate and then assemble them into a polishing machine, this plate have a standard dimension and the plate have to be set with the suitable qty to cover the plate surface completely for polishing, so that if the products dimension is small (5mm~50mm), one plate must set several parts for polishing. If there’s 3 pieces on one plate, when you request only one piece, the other two pieces will be threw, so that one piece price is nearly the sum of 3pcs. Maybe you can understand why the more the qty is the lower the price will be.

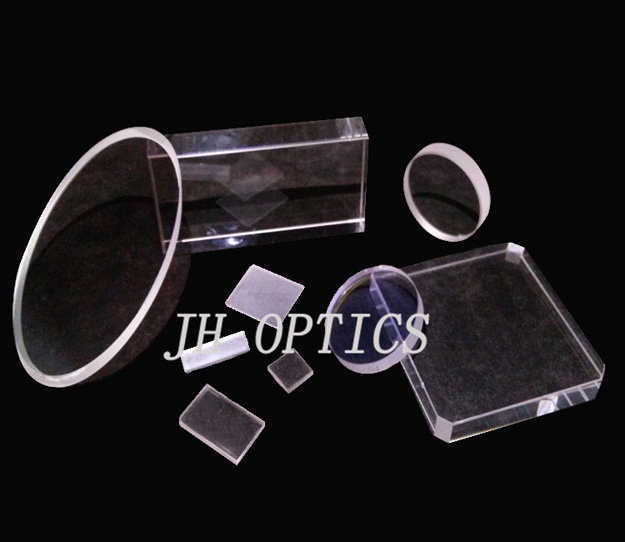

In the following summary, you will get to know more about our products:

As for the differences between physical and chemical properties of each kind material, they can be made with different levels of surface quality.

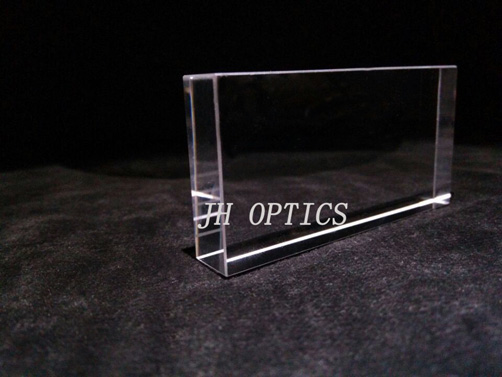

1.N-BK7,UV F.S.

--Square windows

L×W surface flatness wavefront distortion surface quality parallelism

5mm×5mm ~ 50mm×50mm λ/10 λ/8 10/5 2arcsec

60mmx60mm ~ 100mm×100mm λ/8 λ/8 20/10 5arcsec

110mm×110mm ~ 140mm×140mm λ/4 λ/6 40/20 5arcsec

150mm×150mm ~ 200mm×200mm 1λ λ/4 60/40 1arcmin

--Circular windows

Diameter surface flatness wavefront distortion surface quality parallelism

5mm×50mm λ/10 λ/8 10/5 2arcsec

60mm~100mm λ/8 λ/8 20/10 5arcsec

110mm~140mm λ/4 λ/6 40/20 5arcsec

150mm~200mm 1λ λ/4 60/40 1arcmin

2.CaF2

--Square windows

L×W surface quality

5mm×5mm ~ 30mm ×30mm 10/5

35mm×35mm ~ 50mm ×50mm 20/10

60mm×60mm ~ 120mm ×120mm 40/20

--Circular windows

Diameter surface quality

5mm~30mm 10/5

35mm~50mm 20/10

60mm~120mm 40/20

3.Si

--Square windows

L×W surface quality

5mm×5mm ~ 50mm ×50mm 20/10

60mm×60mm ~ 120mm ×120mm 40/20

--Circular windows

Diameter surface quality

5mm~50mm 20/10

60mm~120mm 40/20

4.ZnSe /Ge

--Square windows

L×W surface quality

5mm×5mm ~ 50mm ×50mm 40/20

60mm×60mm ~ 90mm ×90mm 60/40

--Circular windows

Diameter surface quality

5mm~50mm 40/20

60mm~90mm 60/40

There are some pictures or reports for the products , for more information please view their pages.